Digitising assets in every industry

With all its expertise, scanning equipment and modeling skills, the Allinq Insite team can digitise and visualise telecom assets within no time. Using a virtual version of, for example, a telecom mast, a network owner can quickly see what possibilities it offers. In this way, Allinq Insite helps its customers to optimally manage and use their assets. But what if you now also can use that technology, for which the company has developed complex algorithms and generators, in other industries? Then there are opening up wonderful opportunities; for Allinq AND for asset owners!

Two industries, one mission

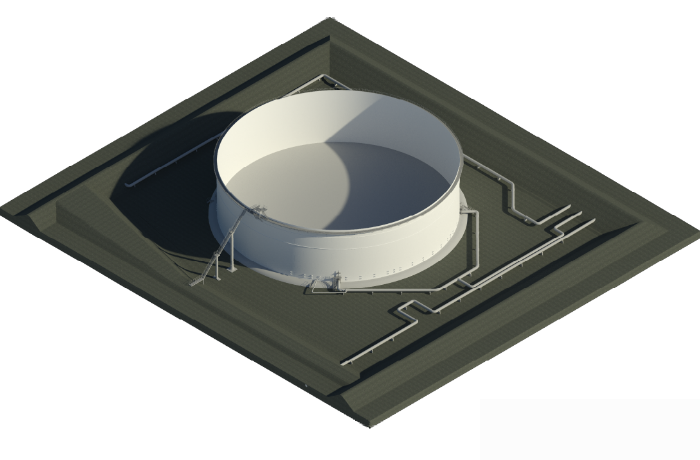

When one of the employees of Allinq Insite met with the CIO of a fellow asset designer in the chemical industry at an expo, the two discovered that they are working on a similar solution for each of their own industries. Where Allinq Insite has used its 3D knowledge in the telecom industry, the other company is widely experienced in digitising oil tanks. In an enthusiastic conversation about digitisation and smart asset management, the gentlemen discovered that certain issues at stake in the chemical sector, already had been tackled by Allinq Insite within the telecom industry. That discovery turned out to be the start of a fun collaboration in which the companies make full use of each other’s expertise.

Modeling is familiar territory, but…

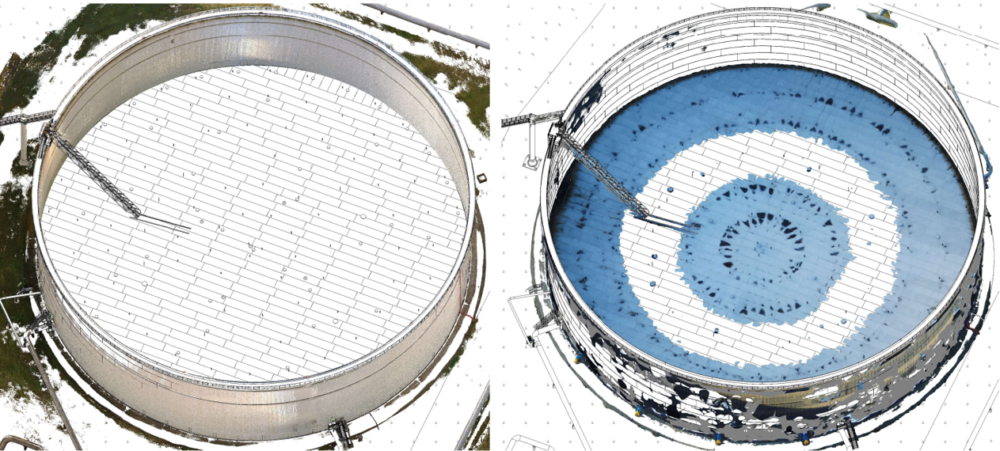

With the knowledge of the telecom market and all algorithms that Allinq Insite has built in recent years, modeling in the telecom sector is now well-known territory. If data is missing when scanning a mast, the missing data can be filled in effectively with the accumulated telecom knowledge. However, this is different for tanks – a completely new market for the Allinq Insite-modellers. The request from the new partner to visualise two tanks as a test was therefore seized with both hands to explore the possibilities together.

Deploying algorithms

The two test cases proved to be such a success that an assignment followed for the next challenge: modeling 100 tanks. This assignment is also tackled by both teams collaboratively. A specialist with in-depth tank knowledge will become part of the Allinq Insite R&D-team for one or to two years. He will teach his temporary colleagues everything important they need to know about a storage tank, of course with the agreement that Allinq Insite will not focus on that industry in the future. That is certainly not the objective of this collaboration; in addition to its ambition to help its brand new partner, it is interesting for the Allinq Insite team to explore how the developed algorithms work in other industries. And that seems to be going well for the time being! The eight-member Allinq Insite team managed to digitise a tank within a week – a task that was previously carried out with a team of 20 workers in a time period of three weeks!

Other industries

The Allinq Insite algorithm also proves to be perfectly applicable in other industries. The company is therefore absolutely open to challenges in other markets. Certainly if companies are willing to really work together: Allowing each other success, really wanting to help each other forward; that’s how we can get other markets moving. Do you have an asset that you would like to have digitised? Or do you see other opportunities with the technology of Allinq Insite? Feel free to contact Allinq Insite at insite@allinq.nl or 0031 – 341 43 71 00.